- Home

- About us

- Dental Plate

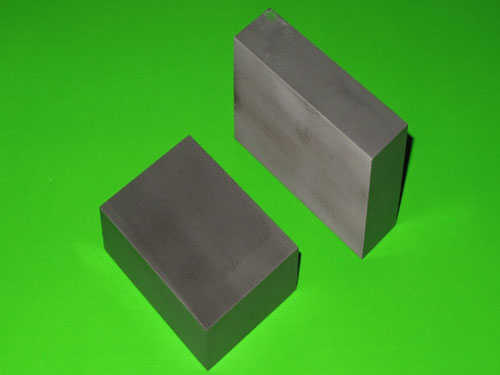

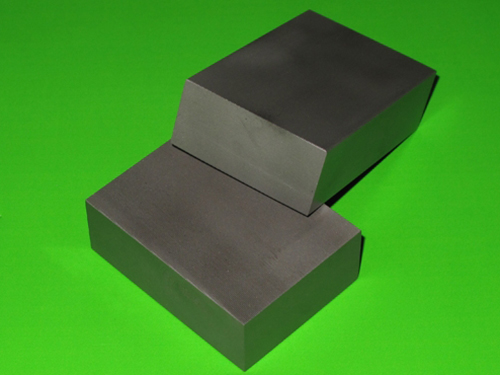

- Rubbing Board

-

Product

Stainless Steel Machine Wire Rolling Board Stainless Steel Self-tapping Plate High-strength Thread Rolling Board Machine Wire Tooth Plate Series Tip-tail Self-tapping Tooth Plate Series Screw Mold Full Range Screw Hardware Series Titanium Screw Thread Rolling Board Series Special Non-standard Tooth Plate Mold Series Imported From Italy And Japan

- Thread standard

- Honor

- News

- contact