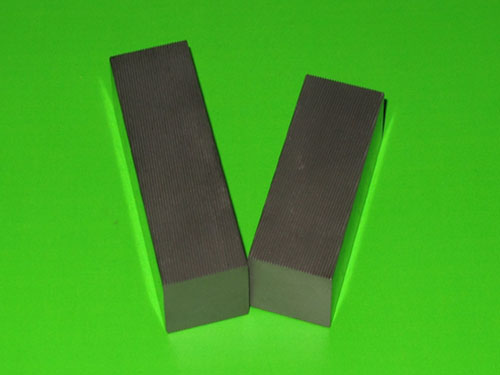

Thread rolling board-Two square stencils used on the thread rolling machine, which are divided into two pieces, one long and one short, with thread patterns on it. It is a tool used to squeeze a screw into a thread. It is one of the screw molds.

The thread rolling board is a special tool for processing taps and bolts.

The thread rolling board is the most commonly used thread tool when processing screws and bolts in the standard fastener industry. The processing principle mainly adopts cold extrusion molding, and cold extrusion molding has high production efficiency, low processing cost, and processed threads. The advantages of high precision, high strength, and good surface quality have been widely used.

Structural form of thread rolling board

The structure of the rolling board has two types: movable rolling board and fixed rolling board.

Working characteristics of thread rolling board:

The thread rolling board must have extremely high hardness, wear resistance, sufficient strength, certain impact force, and strong fatigue resistance.

According to the working conditions of the thread rolling board, the selected material should have the following properties:

(1) Good hardenability, high matrix hardness, good wear resistance;

(2) Good dimensional stability;

(3) Good impact toughness and appropriate strength;

(4) Good machinability and hot workability.