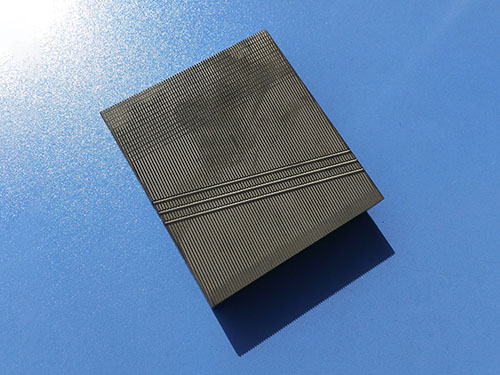

The biggest difference between the thread rolling board and other conventional products is the use of a special surface heat treatment process, which makes it possible to manufacture more screws with clearer surface teeth and maintain the same performance throughout the use process. Sex. Its durability reduces the number of replacements of the thread rolling board in the production process, reduces the loss of machine opening and downtime, and improves production efficiency.

The thread rolling tool uses the plasticity of metal to rotate the material to roll out the thread within the interval of two or more thread models (thread rolling template) as a group. The difference between rolling thread and cutting thread is that the fibrous structure of the material is not cut and is continuous along the tooth crest, so the strength is increased by about 20%, and the accuracy and stability are relatively stable, and the processing surface will not be like the burr or the cutting thread. Bite marks.

1. High production efficiency and wide application range;

2. Product precision, processing surface and strength are all excellent;

3. No cutting material, can save 15-20%;

4. The tool has a long life, which can save the time of program adjustment;

5 Almost all types of threads can be processed, such as metric, imperial, American, aviation threads, and even solenoids.