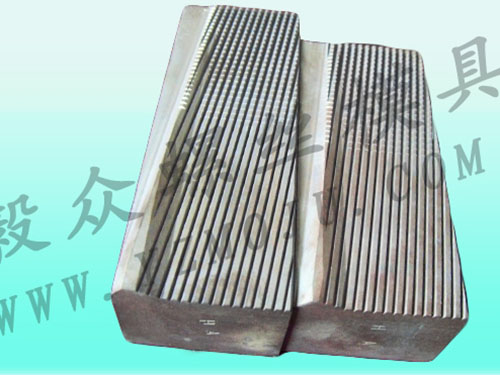

1. The production precision is higher and more accurate.

2. The data can be guaranteed to be consistent no matter how long the thread rolling board is produced. The thread rolling board produced this year is absolutely the same as the one produced next year, which ensures the stability of the screw manufacturer's production quality.

3. The shape of the tip tooth plate is better, avoiding the traditional Taiwanese technical quality that mainly depends on the experience, style and mentality of the production technicians. Now, as long as the parameters are input, everything is under control. The broken tip of the screw is generally frustrated a few times in the broken tip repair area. The broken tip can generally be repaired. The dental plate can be repaired without removing the machine. Be careful not to frustrate the cutting area. Flopping to the cutting area can easily cause the tail of the bee to continue to be cut.

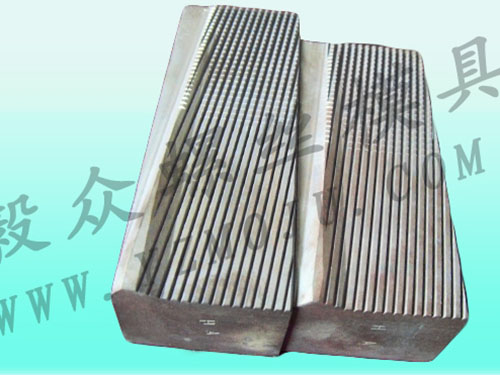

The service life of the stainless steel dental plate is also very much related to the method of the master adjusting the machine. Some masters press the stainless steel dental plate into the material very tightly, and the front end of the stainless steel dental plate will easily wear off. The board emits a lot of smoke during the production process, which will seriously affect the service life of the dental plate. Therefore, it is best to lay the dental plate flat and slowly press it to the proper position. Because its strength and hardness are equivalent to carbon steel (grade 6.8) under normal conditions, stainless steel products should not be impacted or beaten, and care should be taken to maintain the surface finish and precision, and no force or force should be applied like carbon steel products. Too big,

At the same time, due to the good ductility of stainless steel, the steel chips generated during use are easy to stick to the nut teeth, increase the friction force, and easily lead to locking. However, even if the iron chips are produced using carbon steel, they will fall. Stainless steel is not easy to lock up.

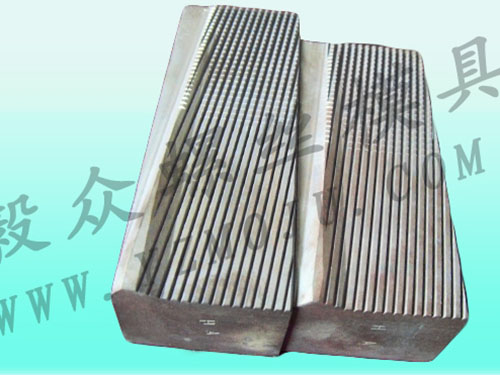

The stainless steel material model has a lot to do with its service life. Commonly used are 302, 304, 316, 201, 667. When ordering stainless steel dental plates, select the appropriate material and heat treatment process according to the stainless steel material model. The service life of the stainless steel tooth plate has a great relationship with the performance of the machine, the oil product, the degree of machine age, the size of the gap, etc. The performance of the machine is stable, the wear on the stainless steel tooth plate will be much less, and the service life will be increased. The oil must be Choose special rubbing stainless steel screw oil.