Dongguan Dalang Yizhong Stainless Steel Dental Plate Information: For the bolts and screws we use daily, there is a certain difference in essence, which can be mainly analyzed from the following aspects:

The most obvious difference between bolts and screws is the head: In the hardware tool manual, only the ordinary hexagonal head is called bolt, and the remaining hexagonal, countersunk, and round heads are all called screws.

The difference in the structure of bolts and screws: bolts have multiple styles of "heads"; studs have no "heads"; screws also have multiple styles of "heads".

However, the structure of the "head" is different. The head of the bolt is mostly hexagonal, which is generally larger; the "head" of the screw is generally equipped with a fastening groove (a slot, a cross groove, etc.), an inner and an outer hexagon And so on, the screw that can be tightened by hand will roll the pattern on the "head", which makes the size of the screw smaller.

The difference in the application of bolts and screws: bolts are generally used in pairs with nuts, which are used for through holes, and can be easily replaced after damage; studs are also generally used with nuts, which do not have a connection effect, and are mostly used for blind holes, tools Generally use a wrench, and the connected parts need to be disassembled frequently; screws usually do not need nuts, and directly match with two objects (generally, the connecting parts need to be drilled and tapped). They are also mostly used for blind holes. The tools are usually screwdrivers (screwdrivers). ), the connected parts are often disassembled.

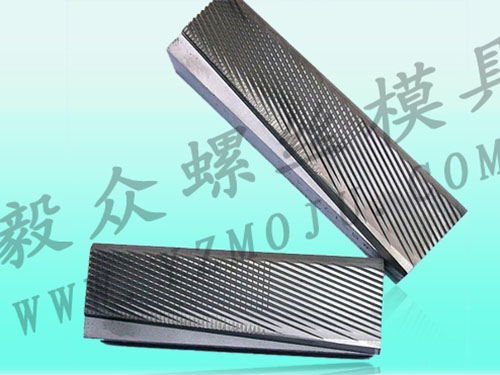

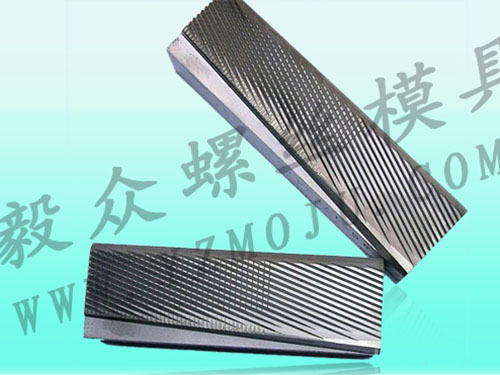

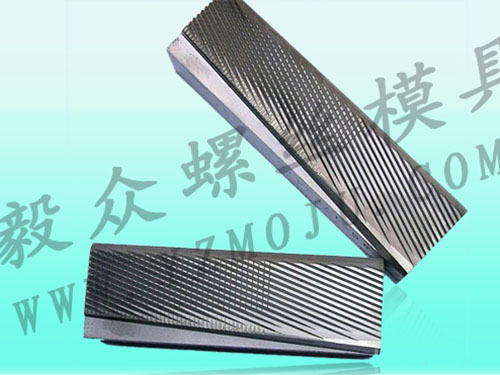

The thread rolling board is divided into three levels of accuracy: level 1, level 2, and level 3. Level 1 is suitable for external threads with tolerance levels 4 and 5; Level 2 is suitable for external threads with tolerance levels 5 and 6; Level 3 is suitable for external threads with tolerance levels 6 and 7 .

The biggest difference between the thread rolling board and other conventional products is the use of a special surface heat treatment process, which makes it possible to manufacture more screws with clearer surface teeth and maintain the same performance throughout the use process. Sex. Its durability reduces the number of replacements of the thread rolling board in the production process, reduces the loss of machine opening and downtime, and improves production efficiency.

The thread rolling tool uses the plasticity of metal to rotate the material to roll out the thread within the interval of two or more thread models (thread rolling template) as a group. The difference between rolling thread and cutting thread is that the fibrous structure of the material is not cut and is continuous along the tooth crest, so the strength is increased by about 20%, and the accuracy and stability are relatively stable, and the processing surface will not be like the burr or the cutting thread. Bite marks.

1. High production efficiency and wide application range; 2. Good product accuracy, processing surface and strength; 3. No cutting materials, which can save 15-20%; 4. Long tool life, which can save programming time; 5 Almost all types of threads can be processed, such as metric, imperial, American, aviation threads, and even solenoids.