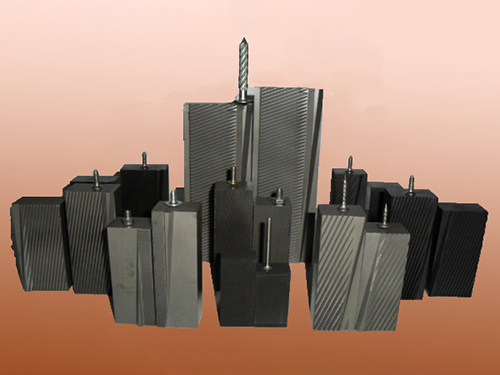

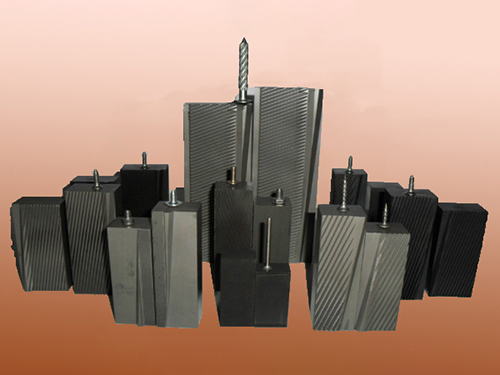

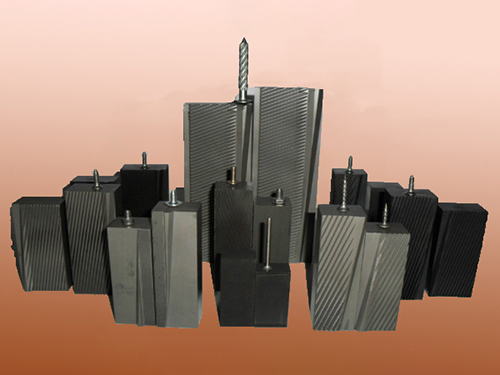

"Drilling self-tapping screws" are also known as "drilling screws", "drilling screws" and "self-drilling screws", also known as "dovetail screws" by northerners. This kind of screw has a drilled tip, and the tip is like a twist drill. During assembly, the screw can drill the center hole by itself, and then tap the adjacent thread part to squeeze out the matching hole in the hole on the carrier. Thread, so it is called self-drilling and self-tapping screw.

The self-drilling screw is a new invention in recent years. Screws are a common term for fasteners, a daily spoken word.

The tail of the self-drilling screw has a tail-drilling or pointed tail shape, and no auxiliary processing is required. It can be drilled, tapped and tightened directly on the set material and base material, which greatly saves construction time. Compared with ordinary screws, its toughness and holding force are high, and it will not loose after a long time after combination. It is easy to complete the operation by using safety punching and tapping at one time.

Usage: It is a kind of wood screw, which is mainly used for fixing the color steel tile of steel structure and can also be used for fixing of thin plate of simple construction. It cannot be used for metal-to-metal bonding and fixing.

When using screws, if you can first understand the mechanical properties of the screws, then you can use the screws better. Different types of screws have different mechanical properties, and the different mechanical properties lead to different occasions when screws are used.

First, self-tapping screws: mechanical performance requirements

1. Heart hardness: standard value HRC28-38. The test is carried out on a section 1-2 times the nominal diameter from the tail. If the nominal length is too short, it can be embedded first, and then the hardness is measured.

2. Surface hardness: standard MIN HV450.

3. Carburized layer: standard 4#-6#: 0.05-0.18mm, 8#-12#: 0.10-0.23 mm, 14#: 0.13-0.28 mm. The main purpose of carburization is to increase the surface hardness and ensure the strength of the teeth. If the decarburization is too deep and the carburization is insufficient, the strength of the teeth will not meet the requirements, that is, the teeth will be damaged during the screwing test.

4. Torque: standard specification 4#5#6#7#8#10#12#14#A tooth 14212835455696145AB tooth 142128354565102165.

5. Screw-in test: Screw the self-tapping screw into a steel plate with a reserved test hole. The self-tapping screw should form a matching thread in the test plate, and the screw thread itself will not be deformed or damaged. Until the end taper thread completely passes through the test plate. The screw-in test is only suitable for AB, B, BP and other types of self-tapping screws. The IFI stipulates that the test plate shall be made of semi-hard low-carbon cold-rolled steel, and the hardness of the steel plate shall be 70-85HRB Rockwell. The standard specifications and thickness of the steel plate are shown in the table below. The test hole should be punched or drilled. The allowable error is the specified nominal diameter (see the table below) ±0.025mm. Specification 6#7#8#10#12#1/4 Test plate thickness (mm) 1.85-1.953.12-3.234.68-4.84 Aperture (mm) ±0.0252.953.263.454.044.765.50.

Second, wall board nails

1. Heart hardness: Standard: HRC24-45.

2. Surface hardness: Standard: HV600-800.

3. Carburized layer: 4#-6# 0.05-0.18mm, 8#-12#0.10-0.23, 14# 0.13-0.28.

4. Curvature: 150 -450 required

5. Salt spray test: generally MIN 48h.

6. Torque: Specification 6#7#8#10# Torque 21283558.

Three, self-drilling screws

1. Heart hardness: Standard: HRC32-40 Our company's product is actually HRC31.7-39.0.

2. Surface hardness: Standard: HV600-700 Our company's product is measured to be about HV620.

3. Hard penetration layer: 4#-6#: 0.05-0.18mm 8#-12#: 0.10-0.23mm 14#: 0.15-0.28mm

4. Torque: specifications, tail drilling, screws, TYPE BSDTYPE CSDINCH-LBKG-CMINCH-LBKG-CM4#(2.9)141614166#(3.5)242824288#(4.2)4248485510#(4.8)6170657512#(5.5)9210610011514 #(6.3) 150173156180.